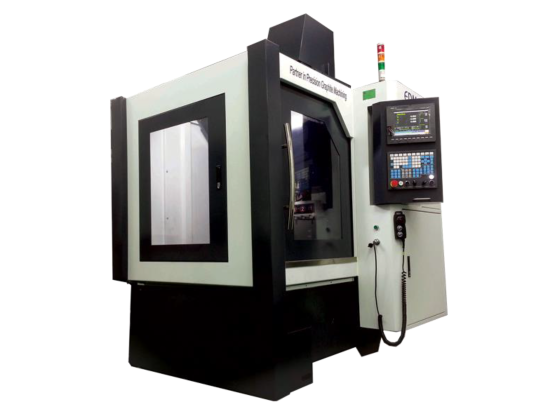

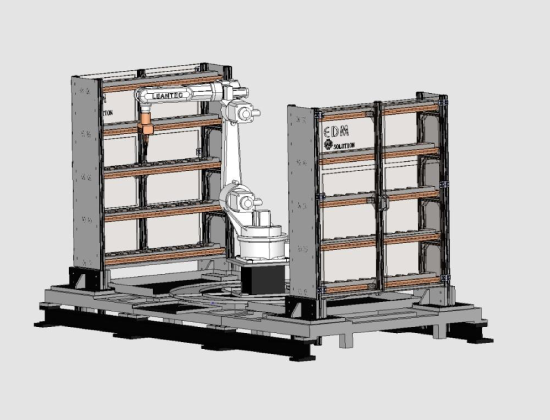

EMS-650T

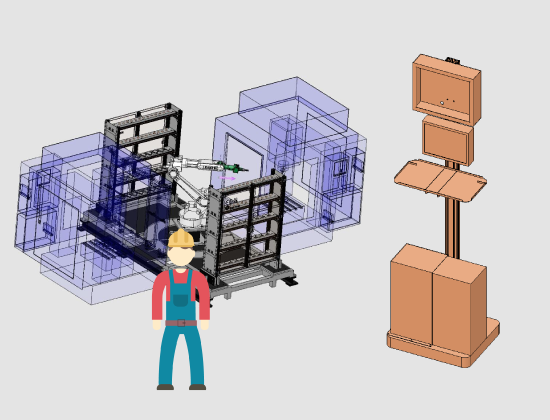

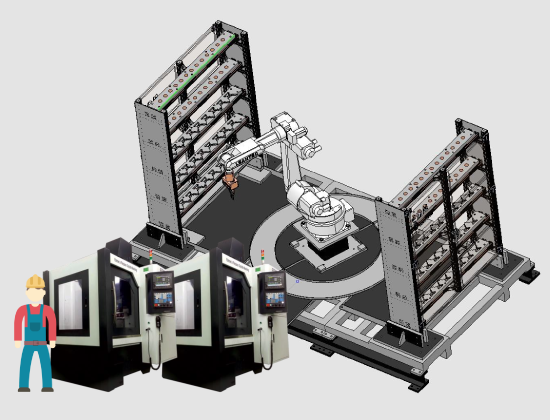

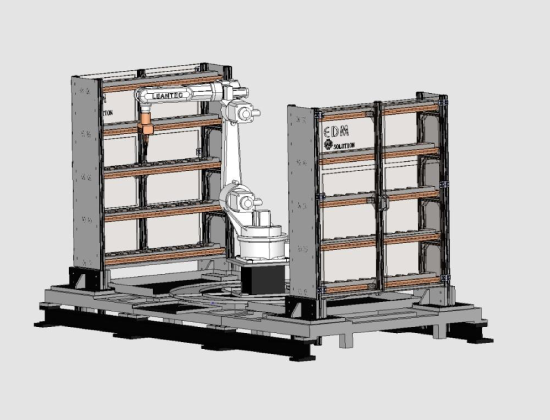

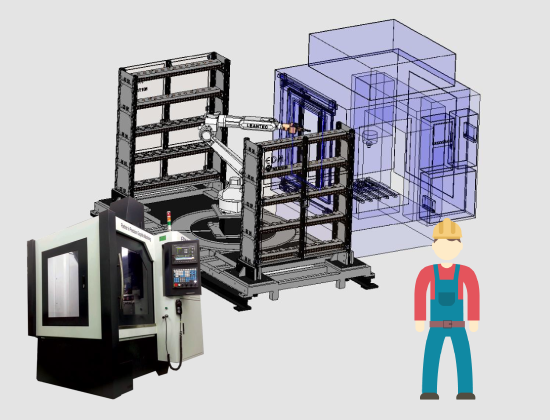

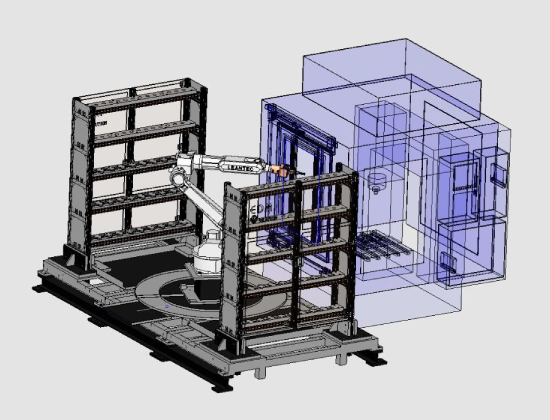

EMS-Automation Solution

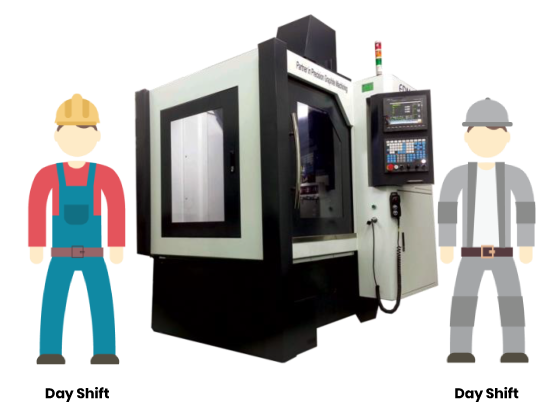

Machine 1

Machine 2

| Machinist | 1 machinist for each machine each 12 hours shift |

|---|---|

| Total staff needed | 4 staffs |

| Staff monthly salary | RM 3,000 per staff |

| Machine max capacity | 16 hour/day |

| Daily maintenance and setting up electrode / workpiece materials | 8 hours machine down time |

| Machining revenue | RM 60/hour |

| Maximum output per day | = RM 60 x 16 hours x 2 machines = RM 1,920/day |

| Machinist | Only one machinist needed for 2 machine running 24 hours |

|---|---|

| Staff monthly salary | RM 3,000 per staff |

| Machine max capacity | 22 hour/day |

| Daily maintenance and setting up electrode / workpiece materials | 2 hours machine down time |

| Machine maintenance and setup time can be consolidated, resulting in increased machine operational time | |

| Machining revenue | RM 60/hour |

| Maximum output per day | = RM 60 x 22 hours x 2 machines = RM 2,640/day |

| Without Robot | With Robot | |

| Max Machine Operational Time | 16 hours/day

|

22 hours/day |

| Max Machine Operational Days | 26 days

|

30 days |

| Maximum Output per Month with

2 machines @ RM60/hour |

RM 49,920 | RM 79,200 |

Monthly capacity increased by 58.65%

Monthly max output increased by RM 29,280

| Without Robot | With Robot | |

| Staff Needed | 4 Staffs

|

1 Staff |

| Staff Monthly Salary | RM 3,000 | RM 3,000 |

| Total Salary | RM 12,000 | RM 3,000 |

Monthly salary savings of RM 9,000

2 units of EMS-650T CNC Milling Machines

2 x RM 258,000 = RM 518,000

1 unit of EMS-Automation Solutions = RM 400,000

Grand Total = RM 918,000